Gravity Gravity Distillation equipment manufacturers distillation equipment safety

Gravity distillation apparatus comprises a distillation column distillation apparatus, reboilers and condensers and other equipment. The main device is a distillation column, its basic function is to provide sufficient opportunity for the gas-liquid contact, the heat transfer and mass transfer processes quickly and effectively; and after making contact with air, liquid two-phase separated in time, and do not entrainment . According to the structure of the tower in the form of gas, liquid contact member, distillation can be divided into two plate column and packed column types.

A plate column

Structure (a) plate tower

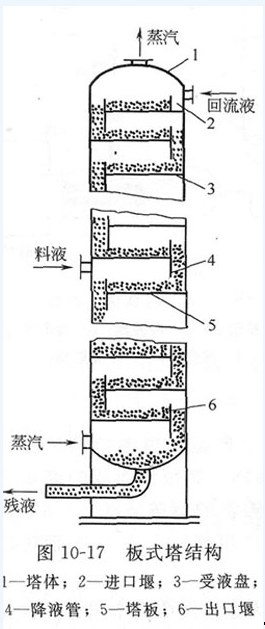

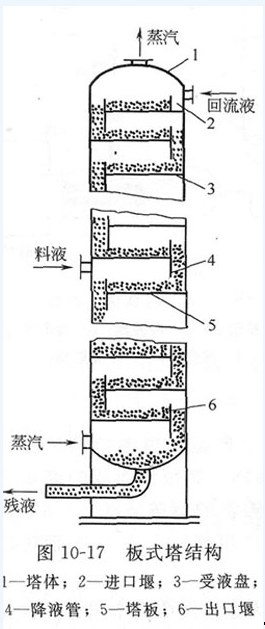

Plate tower is usually caused by a cylindrical housing and a plurality of layers of trays along the tower height by a certain distance horizontally disposed of the composition, shown in Figure 10-17. When operated, the liquid is discharged by gravity from the top to the bottom of the column-by-plate, and the liquid layer active layers are formed on the plate tray; gas at a pressure difference is driven from the bottom up through uniform in trays of openings through the layers successively discharged from the top tray. Tower with trays as the gas-liquid contact and mass transfer in two basic components.

Industrial production in the plate tower, often based on the presence or absence downcomer trays between communication and divided into downcomer and without downcomer two categories, the most used are downcomer type of plate column (Figure 10-17 below), which is mainly from the tower, the overflow device and the tray member and other components.

(1) generally cylindrical tower, commonly welded steel plate, and sometimes it is divided into several sections tower, with flange connection between the tower section.

(2) overflow weir means comprises an outlet downcomer, import weir, a liquid pan and other components.

1) exit weir to ensure the gas-liquid two-phase on the trays have sufficient contact time, the trays must have a certain amount of liquid storage. To this end, the plate is provided at the outlet end of the weir, said outlet weir. The thickness of the liquid layer on the tray or liquid holdup is largely determined by the high weir decision. Production of the most commonly used is arcuate weir, a small circular tower is also useful downcomer rose out of the board as an outlet weir of a certain height.

2) downcomer downcomer flow path is between the plates. Is the overflow of the liquid entrained gas separation place. During normal operation, the liquid outflow pipe from the upper downcomer tray, flows across the plate, over the weir, enter the layer tray downcomer, the flow of the lower plate. Downcomer has two circular and arched, arched downcomer downcomer has a larger area, good gas-liquid separation, liquid drop capability, so widely used in the production.

In order to ensure the smooth flow can lower inflow tray and prevents the accumulation of precipitate and clog the flow path between the tube and the lower down the tray should be a certain distance. In order to keep the liquid seal downcomer, to prevent the gas from the lower column to enter the downcomer, this spacing should be less than the outlet weir height.

3) that the bottom part of the pan tray downcomer are often called permanent drip pan. There are two kinds of concave and flat, generally larger tower by using a concave pan, flat surface of the plate itself is.

4) Import weir in the larger tower diameter tower in order to reduce the impact of the liquid from the lower level below the outflow tube, often setting import weir. Available flat or round direct spot welding Ф8 ~ 10mm in downcomer trays around together. In order to ensure smooth flow, the level of imports weir and downcomer spacing interval between the downcomer and trays of not less than.

(3) the tray and the tray is a plate tower gas component, place liquid contact, the quality of gas, liquid on the trays when contact operation, heat transfer, mass transfer efficiency greatly affected. In the long-term production practice, people continue to research and develop new trays, the trays in order to improve the gas, liquid contact condition, improve efficiency plate tower. Industrial production is currently more widely used types of trays Blister trays, sieve trays, valve trays, such as several, but the bubble column has been less and less.

Type (b) plate tower

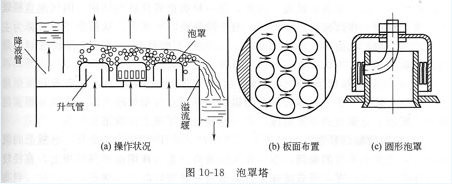

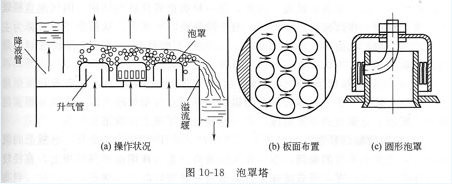

(1) a bubble column with the establishment of industrial bubble column is distilled and developed, is the application of the first tower, the structure shown in Figure 10-18. The main element of the blister trays, blister size is generally 80,100,150 three kinds, according to the diameter of the column size to choose, the bottom of the blister opened Chifeng, blister mounted on the riser, from a tray under the rising gas blown through the riser from Chifeng, the top riser should be higher than the upper edge of the blister Chifeng, in order to prevent the liquid from leave out, thanks to the riser, even in a bubble column At low gas velocity manipulation, still will not have a serious leakage phenomenon. Therefore, this kind of operation is very stable tower and a complete design information and part of the standard. Less complex structure, pressure drop, high cost, has gradually been replaced by other tower, the new tower and then this little tray.

(2) sieve tray sieve column appeared slightly later than the bubble column, bubble column difference that canceled the blister and the riser, directly open a lot of small diameter mesh plate. When operated, rising gas speed through the holes, liquid board can not fall from the hole, only the tube flows through downcomer lower plate, rising steam or bubble point conditions become intense agitation plate liquid layer foam layer . Sieve made of stainless steel with a diameter of the hole is approximately Ф8mm. Sieve tower structure is simple, low cost, large capacity, high plate efficiency, pressure drop, as deep into the study of its nature, has become the most widely used.

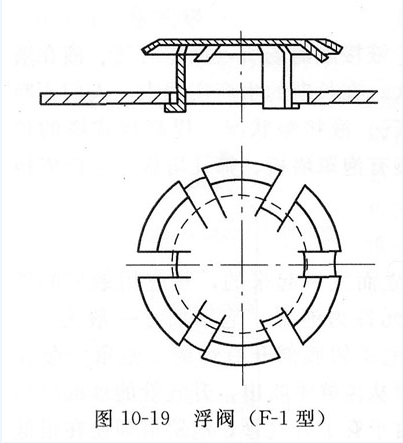

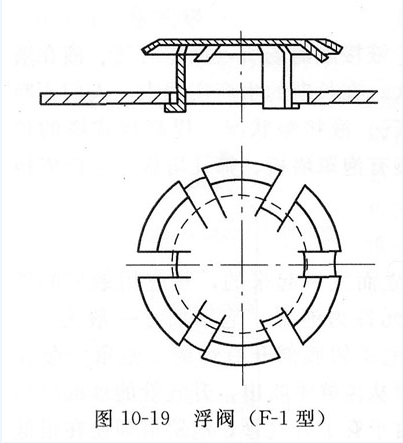

(3) the float valve float valve tower tower began to study after World War II. A new tray used since the 1950s. Its characteristics are installed at each mesh a body floating up and down in the sieve, sieve when the gas velocity is high, the valve is jacked up and rises, the gas velocity is low, the valve drops by its own weight. Body may change with the rise of gas automatically adjust the degree of opening, it will give the trays progress into the liquid layer gas velocity will not change with the gas load changes greatly, while gas is blown from the lower level to strengthen the gas and liquid valve contacts. Many forms float valve. Which type F-1 research and extension earlier, as shown in Figure 10-19. Points of light and heavy valves two valves, valve light weight 25g, stamped from sheet made of 1.5mm; severe valve weight 33g, stamped from sheet made of 2mm. Valve hole diameter 39mm, the valve has three legs hooked, will be inserted into the valve hole hook pull their legs turn 90 °, can be prevented by the gas blown away; in addition, the float valve edge down slightly bent punched out three "feet." When the gas velocity is reduced to low float valve trays, by these three "legs" of the valve plate and the plate to keep the gap between the left and right of 2.5mm.

Chong Hing Chemical Equipment Co., Ltd. focus on gravity distillation equipment, gravity distillation machine production, the company's main products: efficient rotary distillation machine, sampler distillation, desulfurization equipment, sewage treatment equipment (saline waste water treatment) all kinds of stainless steel reactor, heat exchangers, condensers, solvent efficient separation device, retorts, continuous centrifuge.

Zhejiang Chemical Equipment Co., Ltd. Chong Hing

Miss Zhu: 15906488718

Tel: + 86-0577-86997010

Fax: + 86-0577-86997020

E-mail: cxce@zjcxce.com

Website: http: //www.zjcxce.com

Address: Longwan District of Wenzhou City Wing in the streets of the village Feng Ji Road 155