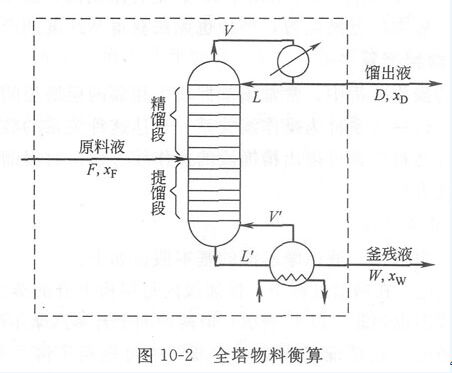

Gravity Distillation equipment manufacturer describes the whole tower material balance

Continuous distillation process, the overhead and bottoms product flow and composition, and it is the feed flow rate and composition related. The relationship between them through the whole tower material balance is obtained. The dashed box shown in Figure 10-2 accountancy within range.

The total mass balance ??? F = D + W ??? (10-1)

Volatile component balance Fxr = DxD + Wxw ??? (10-2)

Wherein the molar flow rate of the raw material fluid F, kmol / h;

D-- molar flow rate of distillate, kmol / h;

W-- bottoms molar flow, kmol / h;

XF-- feed liquid mole fraction of volatile components;

Distillate mole fraction of volatile components;

Bottoms in the mole fraction of volatile components.

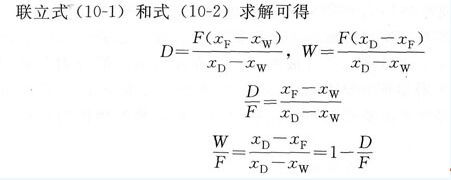

Just four parameters which are known, you can find the other two parameters. Under normal circumstances F, cF, cD, Xw by the production mandates. In the above formula F, D, W may also be used for mass flow, accordingly XF, XD, Xw mass fraction.

Where? D / F, the W / F-- projects are referred to as a distillate recovery rate and raffinate recovery.

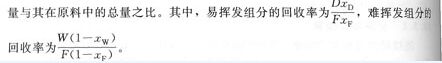

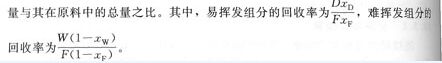

Distillation is also commonly used in the recovery of the concept. The so-called recovery, refers to a component recovered by distillation

Full tower material balance equation is simple, but to guide the rectification production is crucial. Actual production, distillation feed is made before - step brought it, and therefore the feed composition XF is constant. By the formula (10-4) and (10-5) shows that the product yield and composition of the tower is mutual restraint.

ndustrial distillation separation index generally have the following form:

① provisions of the distillate and bottoms composition XD, Xw, in this case, D / F, W / F is constant, the yield of the tower has been determined, you can not arbitrarily choose

② predetermined distillate composition XD. And recovery ratio of D / F, this time bottoms of mining rate W / F and composition XW, can not freely chosen, and vice versa.

③ a predetermined component in the composition of the distillate and its recovery, due to the recovery of ≤100%, i.e. DXD≤FXF or D / F≤XF / XD. Therefore mining rate D / F is limited, when 0 / F made too large, even though this distillation column has a sufficiently large separation capability, the top can not obtain a high purity product.

Chong Hing Chemical Equipment Co., Ltd. focus on gravity distillation equipment, gravity distillation machine production, the company's main products: efficient rotary distillation machine, sampler distillation, desulfurization equipment, sewage treatment equipment (saline waste water treatment) all kinds of stainless steel reactor, heat exchangers, condensers, solvent efficient separation device, retorts, continuous centrifuge.

Zhejiang Chemical Equipment Co., Ltd. Chong Hing

Miss Zhu: 15906488718

Tel: + 86-0577-86997010

Fax: + 86-0577-86997020

E-mail: cxce@zjcxce.com

Website: http: //www.zjcxce.com

Address: Longwan District of Wenzhou City Wing in the streets of the village Feng Ji Road 155